I decided to fire up the laser again, and get some pictures this time. So while I was at it, I decided to check the beam alignment between the visible and burning laser beams. I also got some pictures of the test set-up.

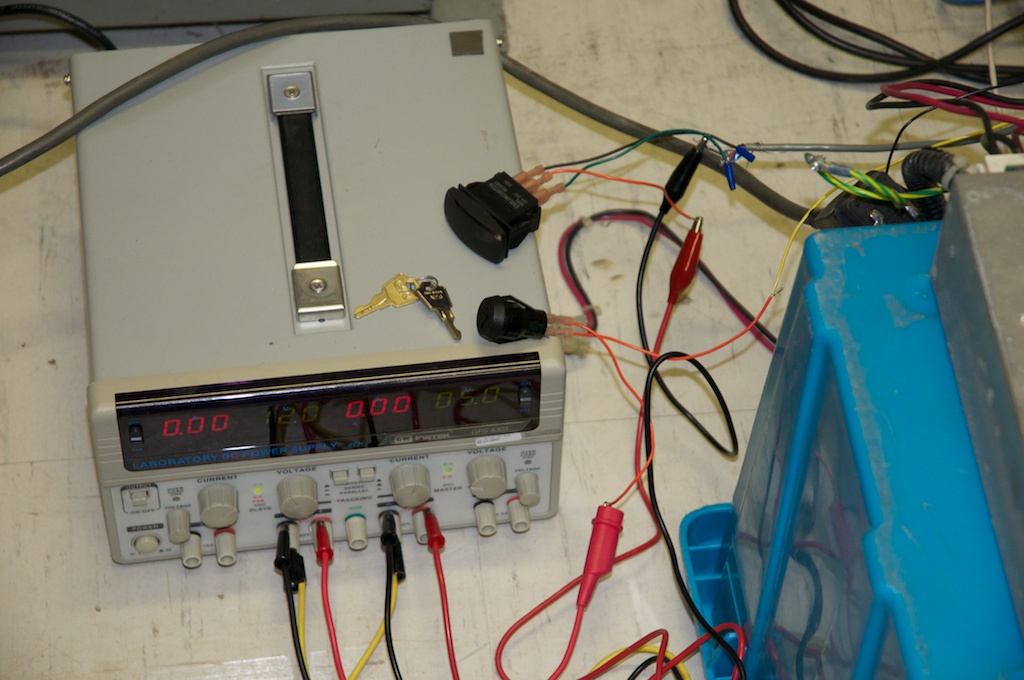

The key switch is for the safety loop, the burning laser will not fire unless the key is in, and turned. The trigger-switch is bi-directional, with one direction firing the red pointing laser, and the other firing the burning laser. There is no reason why the two cannot fire at the same time, it’s just what I had sitting on my shelf. The laser itself requires 12V for the safety loop [it can provide it, but my wiring harness does not have that pin connected] Also required is 5V for the firing control, this must be externally provided. Finally the laser needs 48V to power the laser itself. The 48V is taken from the original power supply, while I am providing the 12 & 5V from a lab supply.

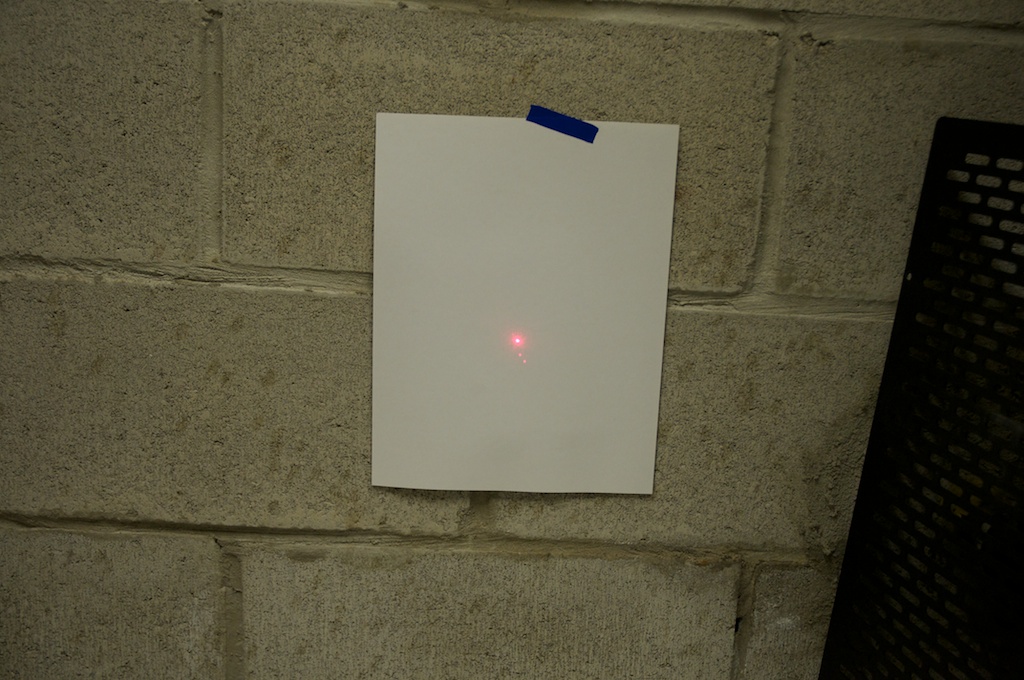

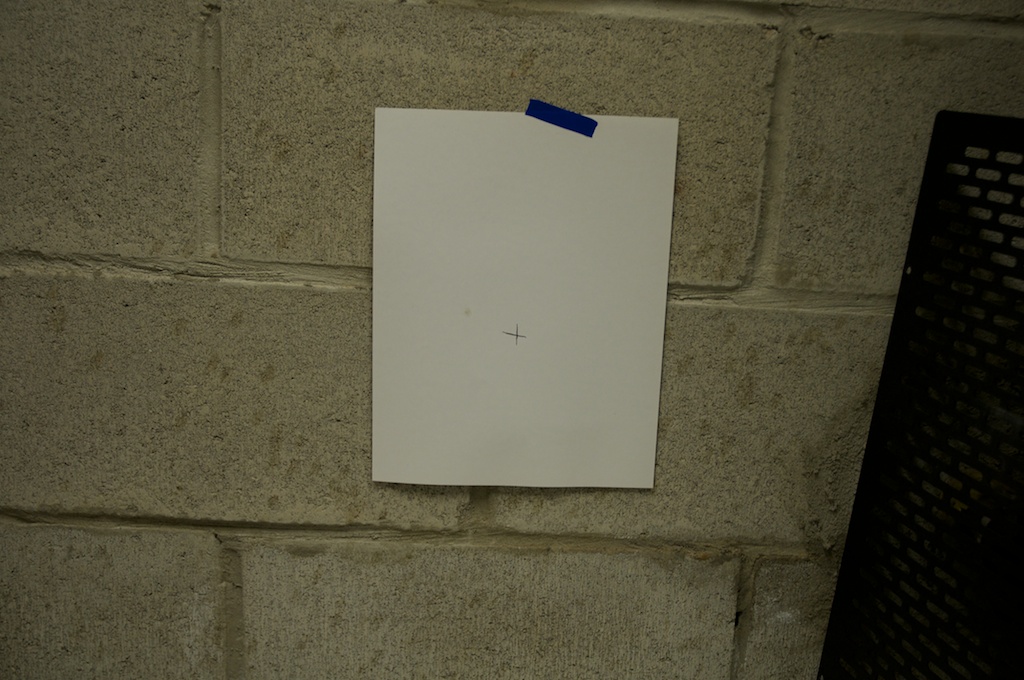

To Check the laser up as above, with a piece of white card-stock taped to a concrete block wall, about 2ft away from the laser. I then fired the visible laser and marked the location of the spot with a pen on the paper.

One might notice that there are 4 red spots. One main bright spot, and 3 more smaller fainter ones. I’m not exactly sure why they’re there, but I’m assuming it is a result of the beam combining optics. They use what is known as a 45° hot-mirror, which reflects the IR light of the laser, but passes the visible light through. This is what allows the two laser beams to be perfectly aligned. So in the case of the ULS laser the setup is as follows.

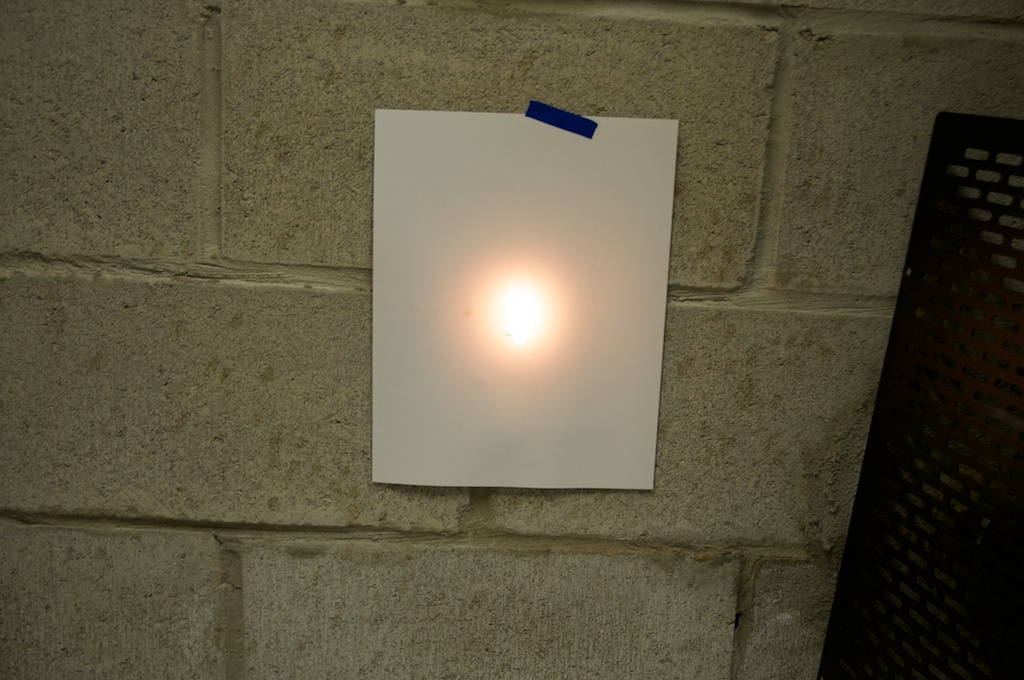

I’m guessing the extra spots are the result of some internal reflections of the red laser within the mirror glass. Either way, they are not an issue. After marking the main spot, I proceeded to fire the CO2 laser, and then re checked with the visible laser. I tried my best to capture the moment of the laser firing, but it just shows up as a large bright white spot. This flash of light is from the material burning, not from the laser itself.

As you’ll see from the image below, the alignment is pretty darn good. So from my perspective, the laser is in perfect operating condition. I may just have to swap out it’s air-cooling fan, as it made some noise the first time I powered it on, though it did not make it again this time around.

So there it is, a fully functioning CO2 laser 🙂 This was probably the last time I fire the laser until I have it back in the enclosure. I don’t like to fire it in the open like this for safety reasons. So for now I’ve covered up the optical aperture on the laser to prevent it from getting dirty, and placed it on the shelf. Hopefully I’ll get a reply from the ULS rep soon, so I can start moving forward on the actual re-assembly of this thing.

Leave a comment