Up next is the Z-lift mechanics [pun intended].

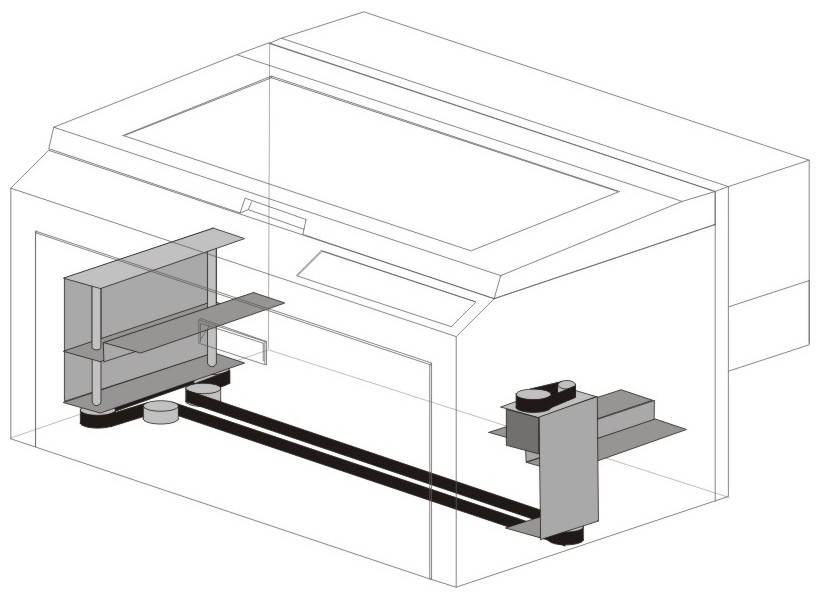

From the mechanical parts of the laser enclosure, these are probably the best preserved. With the exception of one belt that runs from the stepper to the primary lead screw which was about to give [possibly damaged from the heat of the fire], they lift is fully functional. I’ve disassembled it here, in order to clean the parts, and to get the get them painted. The 3 acme lead screws and bearings are in excellent condition, as is the secondary drive belt that transfers power from the primary lead screw to the two secondary lead screws. The stepper motor still turns, but like all the other steppers, it is quite rusted, so I will be replacing it. The stage itself is not likely recoverable, but that is easily replaced. [it is pretty much a consumable, and intended to be replaced periodically] Also included in the Z-lift assembly is a set of upper and lower optical limit switches. [they can be seen in the right hand image along the left edge of the assembly] I have not tested the limit switches yet, but the PCB and components are in perfect condition. Worst case is I’ll have to replace the two optical sensors.

When it comes to re-assembly, this may be one of the harder parts to do right. It may be a challenge to get all 3 screws set to the same level, so that there is not racking on the stage. Once set, all 3 move in unison, so there is no worries of additional racking during use. However, if I’m off, the stage may not move freely, and my etches and cuts will have varying quality from one side to the other, as the distance from the lens will not be constant. So getting it right is critical.

As mine is currently disassembled, here’s a quick youtube video by “lasersafe” showing the mechanism in action, and how it works.

Leave a comment